Technology

Contact Us

Sales Department Tel:

0534-5433137 / 0534-5433136

Technical Department Tel:

18866073876 / 0534-5434137

Address: Xinghua Road, Qihe Economic Development Zone, Shandong, China

Engaged in the development of drying equipment enterprises in the industry are introduced to improve the new products and new products mainly rely on mutual imitation, the future enterprise needs to seek the upgrading of new technology, and energy saving technology will be one of the key. Production enterprises should be based on changes in market demand, drying equipment should be continuously upgraded to become mechanical equipment, energy conservation and environmental protection of the new choice.

Drying equipment should follow the resource-saving development road, carry out comprehensive and multi-level energy-saving technical transformation, and vigorously develop the application of renewable energy and industrial waste heat drying technology. To implement the efficient and green drying development strategy, we must first take the resource-saving development road, change a single, extensive, dry as a combination, intelligent drying. Not only should we make a radical transformation from the drying process, but also carry out a comprehensive and multi-level energy-saving technological transformation, and vigorously develop the application of renewable energy and industrial waste heat drying technology. Along with the social progress and the development needs, the mechanical equipment industry also transforms from "the traditional industry" to "the energy conservation environmental protection type industry", has become the profession tendency.

Environmental pollution is small: Do not use, carrying air, dust, material entrainment very little. The amount of solvent evaporation is very small, so it is easy to handle. Closed loop can be used for contaminated material or solvent recovery.

Operation cost is low: This equipment operates normally, only 1-2 people / day. Low speed mixing and reasonable structure, equipment wear little, maintenance costs are very low.

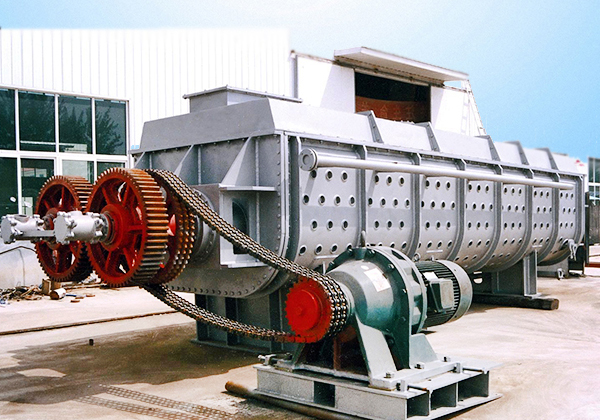

Applications: Paddle dryers have been successfully used in food, chemical, petrochemical, dye, industrial sludge and other fields.

Adapt materials: Environmental protection industry: PTA sludge, electroplating sludge, boiler ash, pharmaceutical factory waste residue, sugar refinery waste residue, monosodium glutamate plant waste residue and coal ash.

There are several parts in the heat transfer surface of the hollow blade dryer, such as blade, mixing shaft, wall and so on. Moreover, the heat transfer area of the blade occupies a large part, so the structure of the equipment is compact and the volume of the unit heat transfer is large. In addition, mixing and mixing make the material stir violently to obtain high heat transfer coefficient, so the occupation space and the space are small, and the construction cost of the building is saved. The drying process has the advantages of less gas consumption, low flow rate and little dust to be taken by the gas, so the gas dust is easy to be recovered after drying, and the recovery equipment is small in size, and the equipment investment can be saved.

The energy consumption of the pulp and leaf drier is low. As a result of indirect heating, no large amount of air is taken away from the heat, and the outer wall of the dryer is provided with a heat insulating layer. The 1kg water is only 1.2kg of steam for the slurry material. The pulp drying system has low cost: it has a large heat transfer surface in the unit effective volume, which shortens the processing time and reduces the equipment size. Greatly reduce the construction area and building space. A wide range of materials with different heat medium, which can handle the heat sensitive materials and processing, the need for high temperature processing materials. Commonly used media are: steam, heat transfer oil, hot water, cooling water, etc.. It can be operated continuously or intermittently, and can be used in many fields.